My current research focus is modeling friction and wear in material forming, multi-scale material modeling and optimization of manufacturing processes related to material deformation. My research activities are supported by key Dutch and European industrial partners mainly in steel, aluminum and automotive sectors. My educational activities are mainly in Mechanical Engineering and Industrial Design programs at different levels: BSc. (Finite Elements Method; Design and Mechanics), MSc. (Computational Structural Optimization) and PhD. (Mechanics of Large Deformations; Nonlinear Material Mechanics).

Organisaties

Publicaties

Jump to: 2026 | 2024 | 2023 | 2022 | 2021

2026

2024

2023

2022

2021

Onderzoeksprofielen

Verbonden aan opleidingen

Vakken collegejaar 2025/2026

Vakken in het huidig collegejaar worden toegevoegd op het moment dat zij definitief zijn in het Osiris systeem. Daarom kan het zijn dat de lijst nog niet compleet is voor het gehele collegejaar.

Vakken collegejaar 2024/2025

Lopende projecten

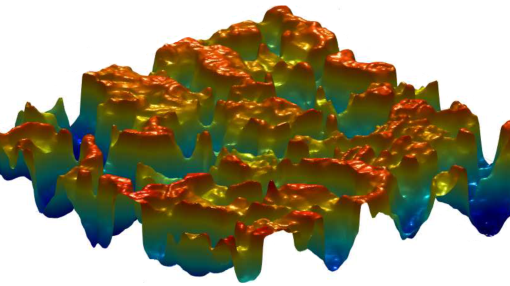

A micro-mechanical model for roughness transfer in cold rolling of steel strips

Multi-scale Friction Modeling in Aluminum Sheet Forming

FORMALUB

Digital Twin: dealing with uncertainties in manufacturing processes

Voltooide projecten

Advanced Simulation and control of tribology in metal forming processes

Model based surface texture design for zinc coated metal sheets

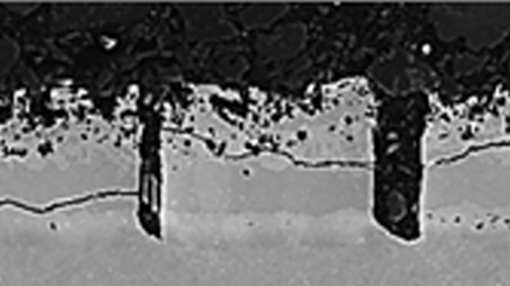

TRIBOLOGICAL INTERACTIONS AND MODELLING OF FRICTION IN HOT STAMPING

Characterization of Al-Si coating fracture during hot deformation

First time right production of metal conveyor belts by active control

Adres

Universiteit Twente

Horst Complex (gebouwnr. 20), kamer N146

De Horst 2

7522 LW Enschede

Universiteit Twente

Horst Complex N146

Postbus 217

7500 AE Enschede